The Evolution of Trencher Machines

Tracing the Development of Trencher Technology Through History

Trenchers—those reliable earth-carving machines dedicated to the noble cause of creating long narrow ditches. These machines are now indispensable in construction, agriculture, and civil infrastructure. Their story is one of remarkable innovation and adaptation. These stories are propelled by humanity’s ceaseless ambition not only to build, but to save our backs from the tyranny of shovels. The evolution of trencher machines is indeed a saga of ingenuity, efficiency, and—let’s be honest—a collective sigh of relief from workers everywhere.

The Dawn of Mechanization: Early Trenching Devices

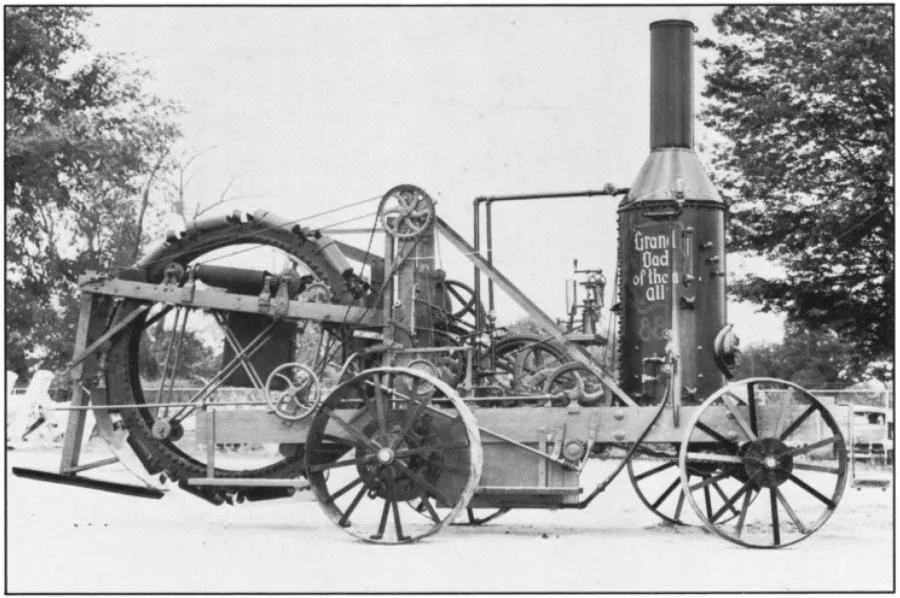

In the late 19th and early 20th centuries, the first mechanized trenchers rumbled into existence. They became powered initially by steam and, later, by the muscle of internal combustion engines. These pioneering machines often began life as agricultural plows or clunky dragline excavators, only to be refitted with attachments for trench-digging. A classic example of turning plowshares into, well, slightly different plowshares.

A major leap forward was the continuous chain trencher, inspired by the humble bicycle chain (who knew your old ten-speed had such potential?). This invention featured rotating chains festooned with buckets or blades, which clawed into the ground and whisked soil away from the trench. This dramatically speeding up the process and conserving worker morale (and possibly marriages).

World Wars and the Acceleration of Trencher Technology

Both World Wars, never one to let an opportunity for innovation pass by, spurred the development of ever more sophisticated trenchers. The demands of trench warfare in World War I, for example, led to machines capable of quickly excavating defensive positions—a much-preferred alternative to sending soldiers out with spoons. Between the wars during World War II, further refinements appeared, including tracked trenchers for greater agility and enhancements in power and operator comfort.

Once the wars ended, these handy advances made their way into civilian life, powering a postwar building boom and, incidentally, ensuring that no one would have to dig a ten-mile sewer line by hand ever again (except perhaps as punishment in particularly strict summer camps).

The Rise of Specialized Trencher Machines

By the mid-20th century, trenchers had diversified faster than the menu at an international buffet. Today, we have:

- Chain trenchers: Modern descendants of the early bucket-chain devices, equipped with robust engines and fearsome cutting teeth to tackle everything from soft soil to stubborn clay—perfect for those who prefer their trenches straight and their workdays short.

- Wheel trenchers: Also called rock wheel trenchers, these machines wield massive, toothed wheels and make short work of hard ground or asphalt. Think of them as the pizza cutters of the construction world—just with less cheese and more horsepower.

- Micro trenchers: The compact heroes of urban environments, micro trenchers carve small, precise channels with minimal disruption to roads and sidewalks, saving city planners from headaches and citizens from detours.

- Portable and walk-behind trenchers: For landscaping and light construction, these smaller models offer flexibility and ease—great for short or shallow trenches, or for those who enjoy walking behind heavy machinery for fun.

The proliferation of these specialized machines reflects the demands of modern infrastructure. Giving a universal desire to avoid manual labor whenever possible.

Materials, Power, and Design Innovations

As technology marched on, trencher machines benefited from stronger materials, superior engines, and sophisticated hydraulic systems. High-strength steels, advanced cutting alloys, and modular wear parts. All of these ensured longer lifespans and fewer awkward phone calls to the repair shop.

Power sources evolved as well: steam made way for gasoline and diesel, and now electric motors and even hybrids are joining the lineup. Modern hydraulic systems deliver pinpoint control. That allows operators to adjust trench depth and width with the mere flick of a wrist—no magic wand required.

Ergonomics and safety have become central concerns. Today’s trenchers feature enclosed cabs, vibration dampening, intuitive controls, and advanced safety interlocks. Making the experience as comfortable and secure as possible for the operator—short of providing a recliner and a cup of tea.

The Digital Revolution: Smart Trenchers and Automation

The 21st century has brought digital wonders to trenching. GPS-guided systems guarantee accuracy to rival even the straightest of rulers. While having sensors monitor cutting depth and machine health, warning operators before any trouble can spoil the day.

Some advanced models offer semi-autonomous or even fully autonomous operation. This following pre-programmed routes and freeing up operators to supervise multiple machines—or simply ponder the mysteries of modern engineering. The data collected by smart trenchers helps optimize maintenance, boost efficiency, and keep projects on track (and, hopefully, under budget).

Environmental Considerations and the Future of Trenching

The environmental impact of trenching is now a major concern. Manufacturers are racing to produce quieter, cleaner, and more energy-efficient machines—good news for city dwellers and endangered earthworms alike. Electric and hybrid trenchers are increasingly common, especially in noise-sensitive urban settings.

Protecting soil integrity and minimizing disruption have become top priorities. Micro trenchers and directional drilling methods allow for installations with minimal surface impact, preserving landscapes. This reducing the need for post-project landscaping (and subsequent complaints).

The future of trenchers will be shaped by ongoing trends in automation, sustainability, and seamless integration with digital construction tools. Tomorrow’s machines promise to be smarter, greener, and even more adaptable. These machines will be ready to dig us into an era of progress with style and efficiency. Trencher chains, sprockets, and rollers are the most important aspect of the trencher. Getting the correct chain for all digging conditions is what makes digging a profit and not a loss. Replacementdiggingparts.com believes in keeping our customers digging and not repairing.